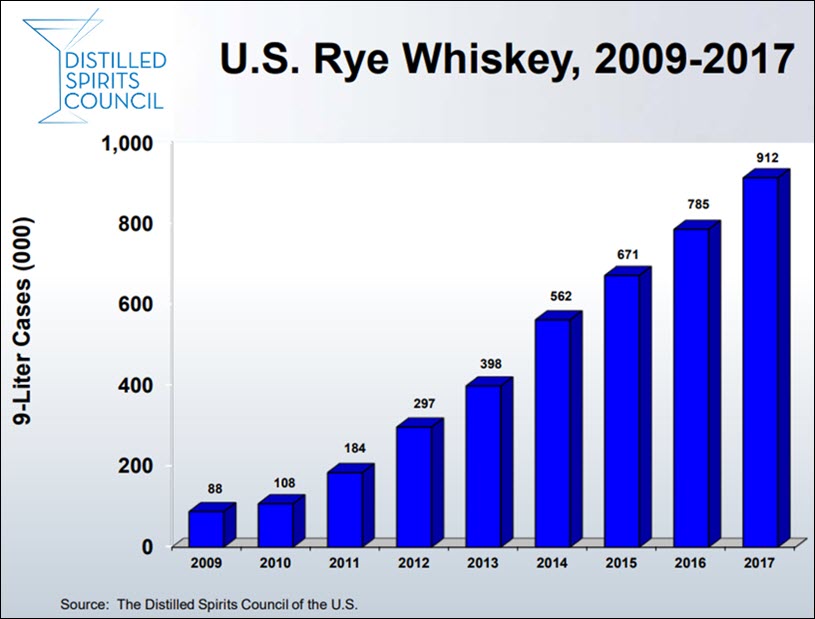

Rye whiskey is very popular these days. We can clearly see the growth in market share. People talk about how unique it is, but then the occasional article surfaces that talks about how blind tastings show that no one can tell the difference between rye and bourbon. If it’s supposed to be so unique and different, why then is it so similar? What is rye whiskey anyway?

This seems like an easy enough question to answer, right? There are plenty of articles out there telling us what rye whiskey is. They explain what the US defines as rye whiskey, what it’s made from, what it tastes like, why it’s what you should buying right now…but I’m here to tell you…you’re not getting the full story. What rye whiskey is today is a far cry from what pure rye whiskey used to be. We find it convenient to compare rye whiskey to bourbon whiskey because bourbon is fashionable and it’s what we’re comfortable discussing. It seems reasonable to imagine that rye whiskey is similar in style to bourbon, just made from rye instead of corn. But that assumption is based entirely upon the fact that most of the rye whiskey on the market today is made by bourbon producers. It’s called the “bourbon boom” not the “rye boom,” so that tracks. But these past few years have given rye whiskey a bit of a boost in popularity. People are showing interest in the history of rye and the uniqueness of the style. It’s been exciting to watch this resurgence, and I certainly hope we continue in this direction, but let’s get one thing straight. Rye whiskey is NOT bourbon whiskey and never has been. There’s a reason Jimmy Russell has said that he “doesn’t like to make rye whiskey.” He’s a bourbon distiller! (And an excellent one, at that!) He and other bourbon makers shouldn’t be making rye whiskey. They should leave that to the rye whiskey makers. But who are they? Are there any experts? What makes them different? What was rye whiskey, historically speaking? How is it different today from what it used to be? Is it possible to try return to a traditional style if that’s what American distillers want to do? I would argue that it is possible. But honestly, we still have a long way to go. Maybe rye whiskey is very similar to bourbon today, but let’s look into why rye whiskey USED to be so different.

“Whisky” (yes, they spell it without the e) is defined in the TTB’s Standards of Identity as;

“Spirits distilled from a fermented mash of grain at less than 95% alcohol by volume (190 proof) having the taste, aroma and characteristics generally attributed to whisky and bottled at not less than 40% alcohol by volume (80 proof).”

The TTB defines “Rye Whisky” as;

“Whisky produced at not exceeding 80% alcohol by volume (160 proof) from a fermented mash of not less than 51 percent rye and stored at not more than 62.5% alcohol by volume (125 proof) in charred new oak containers.”

These differ only slightly from the definition of “Whiskey” in 1935, just after Prohibtion;

“Whiskey is an alcoholic distillate from a fermented mash of grain distilled at less than 190 proof in such manner that the distillate possesses the taste, aroma, and characteristics generally attributed to whiskey, and withdrawn from the cistern room at not more than 110 and not less than 80 proof, whether or not such proof is further reduced prior to bottling to not less than 80 proof and also includes mixtures of the foregoing distillates for which no specific standards of identity are described herein. Rye whiskey, bourbon whiskey, wheat whiskey, corn whiskey, malt whiskey, or rye malt whiskey is whiskey which has been distilled to not exceeding 160 proof from a fermented mash of not less than 51% rye grain, corn grain, wheat grain, malted barley grain or malted rye grain, respectively, and also includes mixtures of such whiskeys where the mixture consists exclusively of whiskeys of the same type.”

The old definition isn’t very different, but you can see that the standards of identity used to include rules concerning withdrawals from the “cistern room.” All operational distilleries used to have designated rooms where the finished distillate was held in cisterns that were accessible only to government gaugers. Once the distillate was gauged and information was recorded, the distillery workers were able to proof down the distillate with pure spring water. They dropped the proof from around 150 (this differed slightly from distillery to distillery) to barrel entry proof which was around 100 proof. The cistern room is a relic of the past. They no longer exist as a necessity in a distillery because gaugers are no longer maintained by the US government’s Department of Internal Revenue. The responsibility for recording this important information for tax purposes now falls to the distillers themselves. While most of what defines whiskey has remained the same since the 1930s, the proof off the still was often lower (which would ultimately retain more congeners or “flavor compounds” in the finished distillate) and the barrel entry proof was lower. A lower alcohol proof means a higher water content in the barrel. And because water is more soluble than alcohol, more water means more extraction from the wood staves. This would certainly have altered the spirit and made rye whiskey taste quite different.

Historically speaking, rye whiskey was almost always aged in steam-heated warehouses which maintained a consistent temperature throughout the year. A low entry proof would have been key in maintaining the integrity of the spirit in a warehouse that was heated all year round. Today, the distillate going into a barrel is usually around 65% ethanol and 35% water. Historically, however, the contents of rye whiskey barrels were 50% ethanol and 50% water. (Those barrels were also smaller than they are today. Rye whiskey barrels used for aging were usually 42-48 gallons.) Since around the Civil War, brick and stone warehouses in Pennsylvania were heated to maintain a steady temperature between 75 and 90 degrees. Each distillery’s warehouse temperature was slightly different, but almost all of them agreed that this practice was absolutely necessary in the aging of rye whiskey. In fact, the practice was universal wherever rye whiskey was being made in the US. What remains unclear is how exactly these warehouses were maintained. I have read that rye whiskey warehouses were “balmy” and that workers were uncomfortable in the heat- even in the winter. I will continue to search for information regarding the methods that were employed in the maintenance of these 7-8 story structures, but it appears that venting windows were employed in maintain consistency of temperature throughout. It does not appear that nature was allowed to take its course as is the case in modern warehouses. The barrels did not cycle through hot and cold with the seasons. They remained consistently heated to above-room-temperature conditions. The modern way that rye whiskey is aged, which is basically the same as bourbon whiskey, is very different and likely not doing justice to the style.

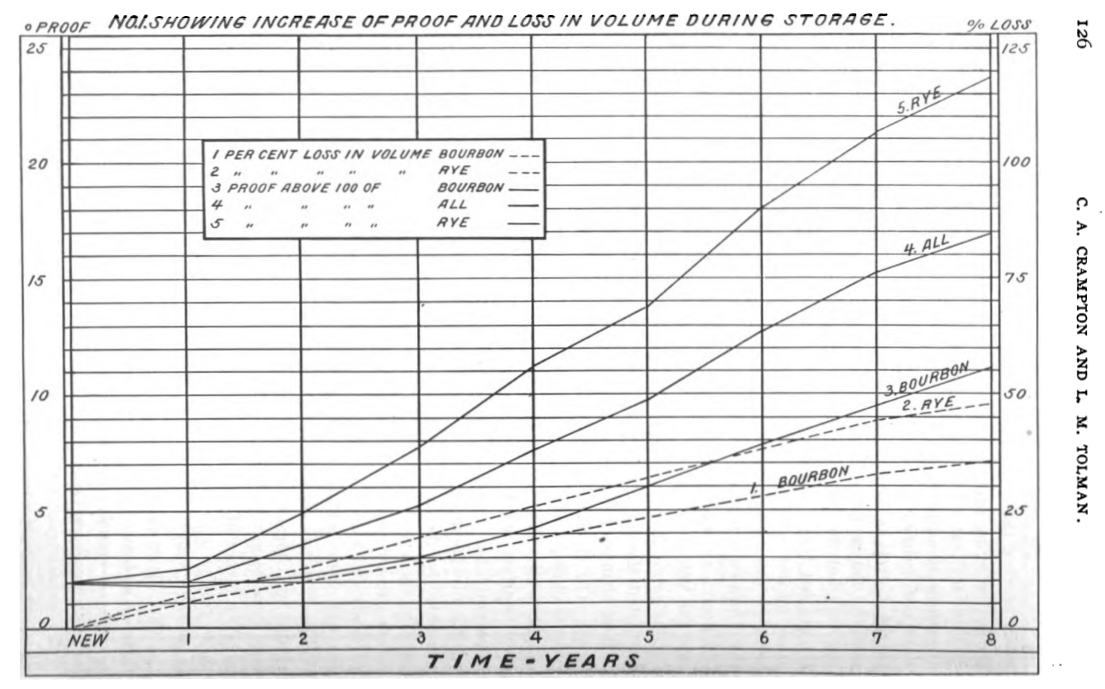

While the old ways used to make rye whiskey were once very similar to the traditional methods employed in Scotland (beer still, spirit still, worm, spirit safe, etc.), the methods of aging were quite different. I mention this because Scotland is known for having a much smaller angel’s share than Kentucky. The climate of Scotland is milder and the air maintains a higher moisture content which keeps the amount of evaporation of each barrel’s contents in check. Scotland’s traditional dirt floor dunnage warehouses maintain cool, moist conditions. What remains to be determined about rye whiskey warehouses is whether the humidity in the warehouse was also kept as high with the temperatures- or if it was a dry heat. This is very important because that would determine the amount of water or alcohol loss that would leave the barrel during the aging process (the “angel’s share”). A government study conducted between 1898 and 1906 (see chart below) showed that rye whiskey barrels sustained the most loss of liquid over 8 years of aging in comparison to the other American whiskeys in the study. What is not clear from the study was what specific conditions in the warehouse were causing that amount of evaporation. The chart below shows that proof went up 25% while the barrels’ contents reduced by half. The barrel is clearly losing more water than alcohol, but not nearly as much as one might think if the steam-heating created dry conditions. There are no large-scale, year-round steam-heated warehouses used to age whiskey in the modern distilling industry, so no modern comparisons can be made. The few heated warehouses that do exist are used to age bourbon in Kentucky, but they are cycle-heated. This means that the distillery raises the temperature in the warehouse for a limited period of time before allowing it to drop again. The cost to heat a large warehouse, while once considered to be a necessity for production, has been phased out as a production cost-saving measure. Without these techniques used to age rye whiskey, there is no way to recreate this traditional style.

The modern production methods that go into making rye whiskey today are largely based on the production methods used by bourbon whiskey makers. While traditional (but expensive) methods for making rye whiskey began being phased out just after Prohibition, pared down versions continued to limp on for about another 30 years. There were several distilleries in Pennsylvania and Maryland that continued to operate, but they began to replace their equipment and processes to keep up with production demands. The rye whiskey distilleries that survived Prohibition were those connected to Schenley, National Distillers, Hiram Walker, and Seagrams (“The Big Four”). While there were dozens of distilleries functioning in Pennsylvania in the 30s and 40s, that number quickly fell in the 50s. Those that did survive the second world war and the efforts to convert production over to industrial alcohol were bought up, dismantled, or used for storage purposes. This loss of distilleries did not remove the industry’s bias for traditional rye whiskey. It did, however, completely alter its production. The old three chamber stills that remained in places like Hiram Walker Distillery and Kirk’s Pure Rye Whiskey Distillery (later Michter’s Distillery) in Lebanon County, Pennsylvania were replaced with column stills in the 1960s. The column still, the loss of heated warehouses, the increase in the amount of corn in the mash bill, the complete elimination in the use of rye malt, and the loss of the old guard distillers from rye whiskey production all helped to reduce the impact of rye whiskey on the liquor market. The character of the whiskey may have been lessened, but the association that Pennsylvania and Maryland had with rye whiskey was never truly lost. Distilleries in Kentucky continued to outsource their rye whiskey production to facilities in the north like Seagrams in Indiana and Michter’s Distillery in Pennsylvania. Outsourced rye whiskey from the old Continental warehouses in Linfield, Pennsylvania was also bottled and labled as different, unrelated rye whiskey brands. The taste and quality of the whiskey may have changed, but the distant memory of rye whiskey’s excellence was very much alive. This truth can be seen as recently as the craft cocktail movement that began in the late 90s and early 2000s. Rye whiskey was almost always the base ingredient in all those classic cocktails, and bartenders were desperate for that flavor again. Sadly, it no longer existed. Rye Manhattans, rye old fashioneds, rye-based Vieux Carre, and even the rye (or brandy) based Sazerac was replaced with the more commonly available bourbon.

The best way, I believe, for me to illustrate just how different rye whiskey once was is to copy a description of the spirit from an old spirits’ manual. The following is an excerpt from “The Liquor Industry” by Morris Victor Rosenbloom. This manual was published in 1935 and revised in 1937 specifically for the liquor industry to “serve as a text-book for the trade” and as an “aid to the layman in getting a well-rounded picture of the liquor industry.” I will follow each paragraph with notes.

“Rye whiskey contains about 60 percent rye, 20 percent corn, and 20 percent malt. As its production is of more general importance than that of bourbon, its distillation must be taken up in somewhat more detail.

- This distinction is both a reflection of the time in which this was written (1935) and of the recipe which the author would have been most familiar (Dillinger Distillery in Ruffsdale, Pa). Dillinger Distillery was famous after 1933 for rye whiskey brands such as Dillinger Pure Rye Whiskey, Possum Hollow Pure Rye Whiskey, Sam Thompson Rye Whiskey, and blends like Hiram Greene and Tom Keene.

“The first step in making rye whiskey is the grinding of the rye to a proper fineness. The ground rye is next weighed and is then stirred in a mash tub containing a quantity of water heated to the proper temperature, depending upon the grade of rye. The heat, which is maintained for a specific length of time, serves to extract certain substances from the gran which later contribute to the flavor of the whiskey. The mash is then cooled and to it is added ground rye malt. Malt is added to the mash of ground rye and has the very important property of converting the starch into sugar. Thus, after the malt is added to the mash it is allowed to stand. The mash is then cooled again and run into the fermenting tubs. Meanwhile, in a separate tub, a culture of pure yeast is being grown. A certain quantity of this yeast is run into the fermenting tubs with the mash and thoroughly mixed.

- A great deal of these details are lost to time. The expertise in the early mashing and fermenting stages of the rye whiskey making process was lost as the master rye distillers passed away. We await the discovery of old notebooks belonging to distillers from those early years, but until then, most of what we know about making rye whiskey comes from the old Seagrams plants which had already converted to column still distillation.

The description of rye malt as the malt used in starch conversion is an important one. Rye malt is different than barley malt and is no longer made in any large quantities. Old recipes for rye whiskey call for the use of rye and rye malt. We have come to believe that all rye whiskey was made with barley malt, but this is NOT TRUE. Even after Prohibition, many rye whiskey distillers insisted on the use of rye malt. This was changed over time as distillery owners sought to save money. The normalized recipe became rye and barley malt- barley malt being more readily available and less expensive.

Yeast once varied from rye distillery to rye distillery. Distilleries held their own “yeast tanks” and “yeast rooms” where the yeast culture was maintained. Distilleries employed chemists whose sole job was to maintain the health and consistency of the distiller’s yeast. It is unclear how different these strains may have been because none of them survive today.

“The yeast immediately attacks the mash, and fermentation begins. At the end of the fermenting period, which varies from 48 to 72 hours, all of the sugar in the rye mash has been converted into alcohol and carbon dioxide. The resulting liquid is “rye beer.” This is then pumped into a reservoir known as a “beer well.” The beer is then ready to be distilled. From the well this “rye beer” is pumped into a charging tank, from whence it flows directly into the top chamber of the still. The still, an elaborate mechanism usually about 24 feet high, consists of three chambers described before. Steam is injected directly into the liquid in the bottom chamber of the still. Vapors are thus generated. These pass into the middle chamber, where presently other vapors are generated and pass into the third or top chamber. When the charge has been sufficiently heated, the vapors begin to pass from this top chamber into a pipe, which in turn passes into a large condenser. These vapors are now water vapor, partly vaporized alcohol, and in part certain highly volatile chemicals. In the condenser they are cooled and liquified. But this condensate varies tremendously in its character. For instance, the first to come through is known as “high wines” and is good for refining whiskey; but the “tailings,” or the last part of the run, are “low wines” unsuitable for whiskey.

- Fermentation times differed from distillery to distillery. Fermenting rye is often considered a difficult task, but I believe this is largely because most distillers are taught to ferment mashes containing corn. Even distillers’ manuals from the very early 1800s describe how to ease the process by adding corn to the mash. Pennsylvania and Maryland distillers usually did not use corn. If all rye and rye malt mashes were the norm, there were very likely specialized techniques that were used by the masters that are lost to us today.

The beer well was a large vat usually located in the basement of a still house from which the fully fermented mash was pumped into the still above.

The three chamber still was ubiquitous. Every description I have read about rye whiskey distilleries from the 1800s and early 1900s either describe some form of chambered still (or, in some cases a fire heated copper pot still) being used as a beer still. It may have been copper or wooden, depending upon the distillery. The three chamber still is then followed by a smaller copper doubler and a condenser or condensing worm. The larger distilleries used very large worms- 800-1000 feet in length. There was no “normal” set up. Each distillery, while similar to other rye whiskey distilleries, had its own design and layout for its stills. This is a common thread shared with today’s small distilleries. While one late 19th century rye whiskey distillery might have a three chamber still as its beer still, it might also have a fire-heated or a steam-coil heated pot still to refine the finished product. It may even have two wooden stills working back-to-back or a combination of a wood still and a copper pot still.

“It is naturally necessary to separate the unsuitable part of the run from the suitable, and this is accomplished in what is called the “tail box.” The box, or tank, receives all of the condensate as it flows from the condenser. Directly in the flow floats a hydrometer which indicates the flow as high wines or low wines. With the help of this indicator and a valve controlling two discharge pipes, one reading the hydrometer is able to separate the high from the low, so that each of these is collected in a separate tank.

- The tail box is sometimes described as the “separator.” This part of the still is usually manned by a single employee whose job it was to monitor the hydrometer and the sight glass on the separator.

“Although the low wines are not suitable for whiskey, they nevertheless contain a certain amount of material which is valuable, and accordingly they are pumped back into the low wine doubler, a tank which is really an enlargement in the pipe carrying vapor from the still to the condenser. Thus, as the still continues to work, the vapors which the beer yields are forced to pass through the low wine in the doubler and thus carry off its useful ingredients. When these ingredients have all been carried off, the spent low wine is removed from the doubler and a new charge of low wine takes its place.

- These stills were a complex system of pipes. There was no automation as there is today, so as stills became more complex, the job of the distillery manager did too. Stills, especially the three chamber stills, were potentially dangerous and required constant monitoring.

“In the meantime, the high wines- which are really crude whiskey- are collected until there is enough to charge the redoubling or refining still. This still is much smaller and simpler than the main, or beer, still. Within it is a steam coil which when the still has been filled, is charged with steam. This raises the temperature of the charge and causes it to vaporize. Again a similar condensing and separating takes place, the low wines being piped back to the low wine tank of the large still. But the high wines from this refining still are pure rye whiskey and are allowed to flow into the “cistern.”

- A rye whiskey distillery did not have the same output of a bourbon whiskey distillery because the amount of distillate that could be produced from rye was not as great as the amount that could be produced from corn. Rye whiskey distilleries usually had an output of 4.2 gallons per bushel of grain while a bourbon producer was over 5 gallons per bushel.

The distillate flowing into the cistern was finished whiskey. It flowed out of the doubler and condenser or worm into those holding tanks.

“This new rye as it flows to the cistern has a specific gravity of 75 per cent or about 150 proof. In the cistern it is reduced or rectified by the addition of pure spring water to around 100 proof, or a specific gravity of 50 percent alcohol. It is now barreled. After barreling, the whiskey is placed in a moderately heated bonded warehouse and allowed to age.

- The description “moderately heated” must have been a post-Prohibition adjustment. Perhaps the “moderate” heating was only to 75 degrees instead of 85.

New rye whiskey, like other distilled beverages such as brandy, or rum, or Scotch whiskey, consists mainly of a solution of ethyl alcohol in water. In addition to these two basic ingredients, it contains small quantities of many others which pass over as vapor in the course of distillation. It is in the nature and amount of these minor ingredients that the differences between whiskies lie. On the average, new whiskey contains the following ingredients in terms of grams per 100 liters:

| Ingredient | Grams per 100 Liters |

| Color | 0.0 |

| Extract | 13.3 |

| Acids | 12.0 |

| Esters | 16.3 |

| Aldehydes | 5.4 |

| Furfural | 1.0 |

| Fusel Oil | 90.4 |

“The whiskey cycle does not end with the production of distilled spirits. True, a straight spirit has been obtained which may now be sold as such. The whiskey does contain some impurities, though, which aging would eliminate. The longer it is aged, the better it will be. American whiskey is aged in new, charred white oak barrels, the theory being that during several years’ aging chemical changes purify the whiskey, and the liquor absorbs tannic acid (with coloring and flavoring effect) from the barrel.

- The aging of spirits does not eliminate impurities, but it does reduce some of them. It was believed in the early 1900s that aging eliminated fusel oils which were considered poisonous. This was found to be false (just after the passing of the Food and Drug Act in 1906), but the aging process did reduce one’s ability to detect their foul scent. The char does help to filter impurities from the whiskey, but purify is going a bit far.

“The effect of the aging process on newly distilled whiskey has been more aptly described by Dr. James M. Doran, Executive Director of the Distilled Spirits Institute, Inc. He explained in his address to Fordham University on March 10, 1936, that “it imparts the characteristic woody taste and brown color, and unquestionably the carbon and char contribution to a very large degree in the aging process, which is both an absorption of the disagreeable odors of the freshly distilled spirits, and apparently has some catalytic action in bringing about a combination of the acids and higher alcohols forming the esters that seem to be the characteristic flavor of a matured liquor. After Repeal, we had quite a flurry in these ways to get at it quicker. People didn’t want to wait; they wanted good whiskey, and they wanted it right away. Many of the processes suggested were tried out. Heating and shaking and passing electrical current through the spirits, and so on, were tried; but you can just sum them up in one sentence: “They will take the newness out, but they almost invariably fail to put the age in.”

- The fact that James M. Doran was the executive director of the Distilled Spirits Institute should give us all pause. Just some background- Doran was given the position of chemist for the Internal Revenue Bureau right out of college. By 1920, he was appointed head of chemical and technical division of the same under Treasury Secretary Mellon. He was appointed Commissioner of Prohibition in 1927 and held that position until 1930 just as Mellon was controversially moving the enforcement of prohibition from the treasury department to the justice department. Doran was making $9000 a year as Commissioner of Prohibition but was getting offers for much larger salaried positions in the private sector. He was appointed Commissioner of Industrial Alcohol from 1930-1933 and- surprise- was appointed Technical Director of the Distilled Spirits Council and Supervisor for the Association of Distilled Spirits Industry in 1933 and when those groups were formed to represent all the functioning distilleries to survive Prohibition. It was rather convenient that Mr. Doran, whose job it was to keep America dry and liquor free, became a voice for the whiskey lobby immediately after Prohibition.

Modern rye whiskey producers do not know the history of rye whiskey production because, unfortunately, there has not been a great deal of interest or many “pure rye” advocates to drum up interest. There was no “Rye Trail” established for all the traditional rye whiskey distilleries because they did not exist by the time the Kentucky Distillers Association was setting up the “KY Bourbon Trail.” The rye whiskey distilleries that remained intact after Prohibition that were owned by Schenley and National Distillers were abandoned in the 50s. There were no advocates for distilling in Pennsylvania or Maryland in the 80s and 90s. There is no “Rye Whiskey Fest” or “Rye Whiskey Heritage Institute” or “Rye Boom.” The history of rye has been co-opted because the only producers of rye whiskey left were distillers that ran their stills a few times a year to fill their rye quotas. (If you want to read why I think rye whiskey did not survive into the modern era you can read about that HERE.) Even the enlightened among us have skewed definitions of what rye whiskey is- like this one on Wikipedia: “American rye whiskey, which is similar to bourbon whiskey, but must be distilled from at least 51 percent rye grain.” Whisky Advocate, which often includes articles about “the greatness that was rye whiskey” goes a bit further in their definition: “Rye is a traditional flavoring grain in both American and Canadian whiskies and often adds a punch of spice, even when used in small amounts. In the U.S., rye whiskey must have at least 51% rye in its mashbill, resulting in a spirit that’s less sweet than bourbon, with bold aromas and flavors.” When official definitions are comparing rye whiskey so closely to bourbon, we know that we’re missing something here. Rye is much older and, while it may seem controversial to say, is more steeped in tradition. Rye whiskey makers spared no expense to maintain the quality of their products for 100 years. Even the modern day whiskey makers like Larry Ebersold, “Godfather of Rye Whiskey,” believed that good rye needed to be paid for in order to be made properly. Ebersold tried to encourage Seagrams to use rye and rye malt in their rye whiskey mashbills but his suggestions were refused. A modern board of directors would never have approved the added expense of rye malt…

Traditional “pure rye whiskey” production has become a forgotten art. We have forgotten the details of rye whiskey so thoroughly that when Todd Leopold of Leopold Bros. Distillery in Colorado announced to the world that he had distilled rye whiskey on his three chamber still, whiskey writers (who specialize in the history of whiskey making) scrambled to find out what a three chamber still was! But we don’t have to keep it that way! We can spread the word about rye whiskey history and how its production has changed over time. Distillers are always looking for that “new and improved production process.” I hope that the “old process” will bring new interest to rye whiskey makers all over the country. Especially in Pennsylvania and Maryland! The craft distilling movement may be the key to embracing the old way of doing things. It takes the desire to spend money to make money. This may be a hard thing to come by these days, but the smaller distillers are definitely changing the game! Here’s hoping…