Every whiskey geek should know how grain is grown. Most don’t. Do you?

It occurred to me that there are very few places where whiskey geeks can really learn about grain farming. Soooo, I’m going to give a step-by-step process- a simple one, mind you! I’m not going to get into fertilizer or crop treatments or rainfall or any of that stuff. Just the steps of how a grain farmer gets the grain in the fields into the whiskey of a small distillery. Notice I said SMALL distillery! The same way that your neighbor’s cow isn’t going into your hamburger, the grain that is grown on your neighbor’s farm isn’t going into your big, name-brand bourbon. Specialty grains, when they are grown specifically for whiskey, are grown on a local farm and shipped directly to a partner distillery. This is how that’s done.

Let’s assume that a distiller seeking a local grain source has found a local farmer that has agreed to partner with him/her. Let’s also assume that the farmer they’ve found knows how to grow that grain and has the means to harvest it. In most cases, the process of connecting a farmer to a distiller involves a learning curve, so NO ONE should ever assume that these relationships are easily made. While farmers and distillers were once closely tied agriculturally based businesses, they have become estranged over the last 100 years, so communication gaps are to be expected. BUT, for the sake of this explanation, let’s assume there’s an ideal scenario. (I never encourage anyone to make assumptions about agriculture, but we’ve gotta start somewhere!) Once the distiller explains how much grain they’ll need for the following year’s production schedule, the farmer can plan how much acreage will be necessary for planting. Winter grains are planted in the fall, require most of the year to grow, and are harvested in the summer. Corn is planted in the summer and harvested in late summer/early fall, so preparations must be made accordingly. Thankfully, farmers and distillers are patient people and know they must lay out plans far in advance. (Farming differs in every location- these assumptions are based on climate norms for the NE united States.)

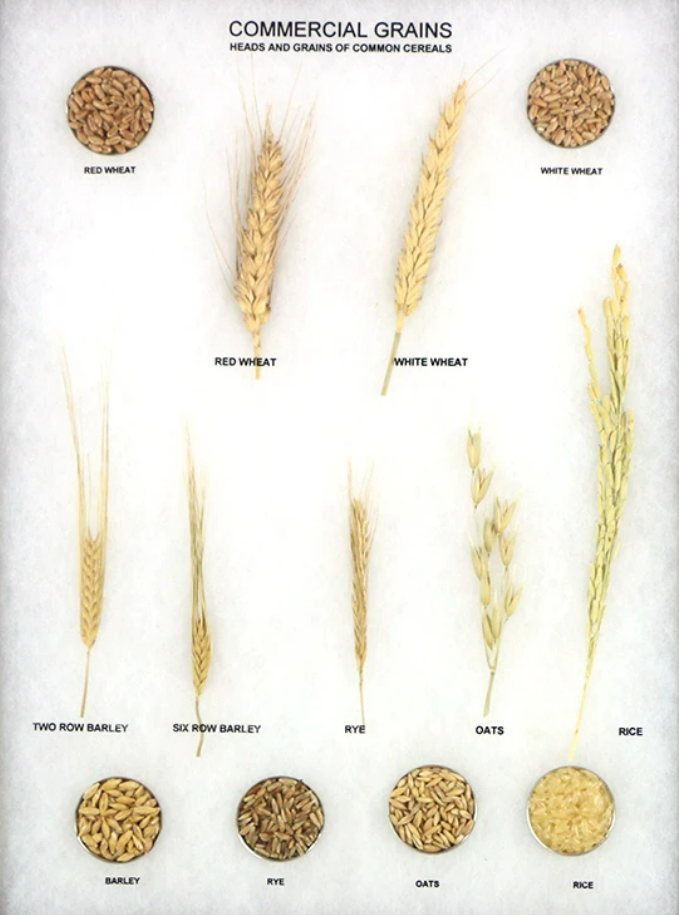

Let’s say the farmer and distiller have decided upon growing 10 acres of winter wheat to make wheat whiskey. Let’s also say that the variety of wheat they decided to grow has a yield of about 60 bushels an acre (in a good year). A bushel of wheat is the equivalent of 60 pounds (rye and corn are 56 pounds per bushel), so at harvest, the farmer can hope to produce approximately 600 bushels (36,000 lbs.) of wheat. Depending on the conditions during the growing season, that number could fluctuate in any direction, so both parties must understand that there are no certainties and that 36,000 pounds is simply the goal, not the expectation.

To plant their 10 acres, they need to buy seed. The farmer must consider how many pounds per acre they’ll need to plant. Let’s say the winter wheat they buy has a seeding rate of 150 pounds per acre- that’s 1500 pounds of seed, or 30 x 50 lb. bags of wheat. Still with me? Winter wheat is planted in the fall, usually in late September/early October to allow the seed to grow and establish itself before the first frost. You can’t plant too early or too late, or you risk crop failure and/or lower yields at harvest- which will be nearly 9 months later! So, the 30 bags of seed are purchased and shipped to the farm in time for planting. That seed is loaded into a machine called a seed drill. A seed drill is an attachment which is pulled behind a tractor. The ground has already been prepped, so the farmer sets the depth on their seed drill (1.25 inches) and plants his/her 10 acres of wheat. Then the fun starts😊

If all went well with planting (and the geese haven’t descended on the fields), the grain will germinate and begin to grow. Once the winter sets in, the plant will go dormant for the winter. It stays green but looks more like grass than any recognizable wheat plant. Not much to do in the winter but let the plants sleep😊

When the ground starts to warm in the spring, many farmers will top dress the crop with fertilizer, but, as I’ve said, we won’t get into that. Suffice it to say that maintenance is required to achieve the best results. The plant begins to go through its growth stages in the spring, starting as greener grass, then sending up shoots called tillers. Each plant will have several tillers, usually 3 or 4, so each square foot of soil can have as many as 75 to 100 tillers! Those tillers continue to grow straight up, making the plant look decidedly more like wheat. Wheat is not a “tall” plant, so it grows to about waist height. Rye and triticale, also winter crops, can grow to be quite a bit taller. The crop needs to be sprayed to control weeds, pests and/or fungus before its heads develop. Once heads develop- the part of the plant that we recognize as wheat- the plant self-pollinates, and the seeds begin to develop. Wheat is self-pollinating and develops its seeds by late spring/early summer, so no worries about cross-pollination. (Rye is a different story😉) Once the crop has completed its life cycle, the plant begins to die, turn yellow, and dry out. This is a good thing because the farmer NEEDS the seeds to dry out! The seeds must be around 13 to 14% moisture content before the combine can do its work. If it rains, the farmer has to wait. The longer he/she waits, the more likely the dying plants will be overtaken by weeds, so harvest time can be a stressful time for farmers! You do not want to taint your grain with weed seeds or worry that your wheat will be contaminated by fungus growth! Moisture content, by the way, is tested with a small electronic device. (Yes, farmers have fancy gadgets, too!) Once the moisture content is right, the combine is called to action.

A combine is much larger than a tractor. It has a rotating head that draws the stalk into the machine as its base is cut. The seed is extracted (threshed) within the machine and the remaining straw and chaff is cast out the back of the machine. The all-important seed is loaded into a storage bin on the combine. (Hopefully, the combine is working well and it is not losing some of the crop on the ground- Losing seed out the back of the combine is NOT a good thing and can drastically reduce the amount of grain harvested, aka “lowering the crop’s yield”.) The combine’s storage bin is emptied (either all at once or periodically) into a receiving truck (grain cart) through an auger. This is usually the image one sees of grain being poured from a tube (much like a hose) into the back of another vehicle. That grain, by the way, is not pristine by any means! The distiller CANNOT just take that grain and distill it! That grain contains other seeds, chaff, bugs, and any number of other particulates.

Once the grain is harvested, it MUST BE CLEANED before being stored. In some cases, the grain may require additional drying to achieve an ideal moisture content for storage. Distilleries want to use grain over the course of months, so the harvested grain must be stored for many months, sometimes as long as a year, so that grain MUST be properly cleaned and dried. Improperly stored grain can be destroyed by bugs or suffer any number of calamities! If the farmer spent a year waiting to harvest this grain, you can be sure they place a high priority on keeping it safe! The cleaning of grain requires a large machine which essentially shakes the grain through screens, separating good, healthy, plump seeds from undesirable particles that the combine may have picked up (rocks, other seeds, bugs, chaff, etc.). Clean, dry grain can then be loaded into storage bins. Sometimes this requires investment on the part of the farmer and distiller because very few farms keep empty bins lying around! Grain bins or silos are designed for storage of grain, but they are not meant to hold grain indefinitely. They often have fans, but they are not refrigerated or heated and MUST be maintained and consistently emptied over time to avoid contamination by mold, bugs or vermin. It is from these bins that the grain is supplied to the distiller as the grain is needed. Then the process starts all over again! Grain is only planted ONCE A YEAR, so when it’s gone, it’s gone. The distiller and farmer can adjust their plans as needed. Perhaps now it’s easier to see why the distiller and farmer used to be the same person- or why so many distilleries have relied on seed brokers to mail them seed when they need it and not concern themselves with farming at all! The problem with this attitude is that whiskey is only as good as its ingredients. The best whiskey is ALWAYS going to come from fresh, high quality, locally grown grain. The more control a distiller has over their grain and its provenance, the better their product will be.

This explanation is a simple one. There’s a lot more to it, obviously. I just hope that I can help to shed a bit more light on JUST HOW DIFFICULT it is to grow grain and how important it is to respect the amount of work that goes into the whiskey you’re drinking. Most farmers prefer to grow commodity crops because there is no need to clean or store those crops- they go straight to the elevator. An elevator is a site where farmers ship their grain at harvest time- usually a large mill or facility that buys grain by the tractor trailer/truckload so farmers don’t have to store it and can get paid immediately based on the quality of their grain. These facilities pay low prices for grain at harvest time and pay more during off-peak months. Elevators store large quantities of grain and act as brokers. They do not separate out varieties of grain or provide provenance for grain. They move grain and lots of it. Farmers are not paid a premium for specialty grains. THIS is the reason that most arguments for “terroir” are moot. As long as distilleries rely on elevators and brokers for grain, they will never possess unique grain sources and will always lack provenance for their grain.

It is the relationship between farmer and distiller that we’ve lost. It is THIS relationship that stands to change the future of American whiskey. I can’t encourage people ENOUGH to learn more about grain!!! Get out there and visit a farm! Ask questions! Learn more! It’s July and harvest is underway…